This quote, attributed to the American footballer Jerry Smith, reflects an universal truth: We all like to hold ourselves as special and unique individuals.

But there are cases where we wished we had a twin:

Imagine a patient facing a serious health condition. He is offered a few different treatments, each one with its pros and cons, and with different success probabilities. Wouldn’t it be great if this patient had a way to “run” a simulation of the different procedures on a “copy” of himself – a copy that would have his exact physical parameters and personal history? After running the several alternatives, the real patient could choose the one with the best result. Awesome, isn’t it?

As Joan Rivers, the American comedian and television host, once said:

I wish I had a twin, so I could know what I look like without plastic surgery.

Science fiction?

Different industries are increasingly leveraging “Digital twins” – a computerized model of the real “thing”, and is used to design, optimize, test, and simulate the “real life” in a safe and harmless environment.

This video by Philips describes exactly the above scenario, using a digital twin for healthcare benefit:

True, human health is the most critical of all concerns. But “digital twin” applications go beyond that: We are increasingly surrounded by machines, robots and systems – that control more and more aspects of our lives. And it’s critical these machines work properly, on their own and with each other.

At his keynote speech at DVCon Europe conference last week in Munich, Dr. Stefan Jockusch, VP of Strategy for Siemens PLM Software, explained how Siemens envisions the future of machinery and factories: each machine has a “Digital Twin”, a computerized model that is as identical as possible to the real machine, and is used to design the systems control, test them, simulate how to best use them and how they may interact with other digital twin of other machines. This could and should be used before the factory is up and running, and once it’s operational, as a preventive maintenance mechanism and to analyse on-going changes and updates to the flow.

The “twin” concept apparently remounts to the early days of space travel, when NASA built replica models of their spacecraft systems that stayed on earth, to help analyze, monitor and fix units that were up in the skies and were not be accessible. As computer technology advanced, this “twin” systems turned increasingly digital, and today incorporate very complex models, including big-data and machine learning algorithms.

If we can apply this concept to the human body and to machines, why not onwards to the more miniaturized level of microelectronics. Here again, computer chips are the core of many critical applications – some times even controlling machines or even human bodies! It is therefore of our interest to create accurate enough models of such chips that can be used to simulate their behavior in many different scenarios.

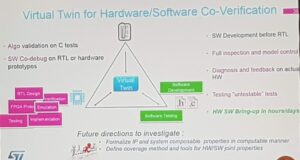

On the Dvcon 2nd-day key-note presentation, Philippe Magarshack, Microcontrollers & Digital ICs Group VP at STMicroelectronics, developed the concept of a “Virtual Twin” for semiconductors.

At first, such Virtual Twins enable verifying algorithms and “hard-to-test” conditions using top-speed C tests, support HW and SW co-debug, and diagnosis and feedback on failures of the physical hardware, just like a healthcare “digital twin”.

As an example, Philippe presented a “virtual twin” model for the STM32 micro controller for IoT applications, based on System-C, full with an ARM M4 instruction set simulator and other peripherals.

For many years and not less now – with the increased complexity of such system – the accurate modelling of the full system continues to be a major challenge, and was the topic of many different presentations. Such models represent, by definition, a higher level of abstraction – or else one wouldn’t be able to achieve its main benefits: a model that is fast to run and a generic enough representation that can be used in different scenarios, reflect different HW/SW partitions and be flexible enough to be modified to explore alternative architectures.

On the other hand, if the model is too high-level, it might not catch some of the issues it was intended to flag – defeating its main purpose.

This topic was covered from many angles at DVCon, at several sessions, under different names: Virtual Platforms, TLM & SystemC models and PSS (Portable Stimulus), all standards and technologies well known and used in the semiconductor industry for the development of system-on-chips and now growing into the development of systems and systems-of-systems.

As a matter of fact, if the subject is challenging enough at the chip-level, imagine when you scale it up to the system level, or the “system-of-systems” domain. As in the example given by ST’s Philippe: what if you want to simulate the inter-operability of 10,000 IoT sensors in a smart-city? “Digital twins” will have to scale up to solve such problems too.

True, the 19th-century American humorist Josh Billings said that

There are two things in life for which we are never truly prepared: twins.

but be prepared: we’re all going to be cloned and get a digital twin: from humans, to machines, down to chips.

*My thanks to Eyck Jentzsch from MINRES for reviewing an earlier version of this article. Eyck presented at DVCon a paper on Virtual Platforms for RISC-V systems.